Mavic factory visit

2019 photos by Stan Koolen

Those who visit France often go for wine, cheese the beauty of nature or a cultural site. But no one will think of visiting the Chamatex or Payen factories in the middle of the Ardèche, one of the most touristic places in France.

2019 photos by Stan Koolen

Those who visit France often go for wine, cheese the beauty of nature or a cultural site. But no one will think of visiting the Chamatex or Payen factories in the middle of the Ardèche, one of the most touristic places in France.

I was invited by Mavic to join one of their press events about how they make the fabrics used for in the latest mavic shoes, jerseys and bibshorts.

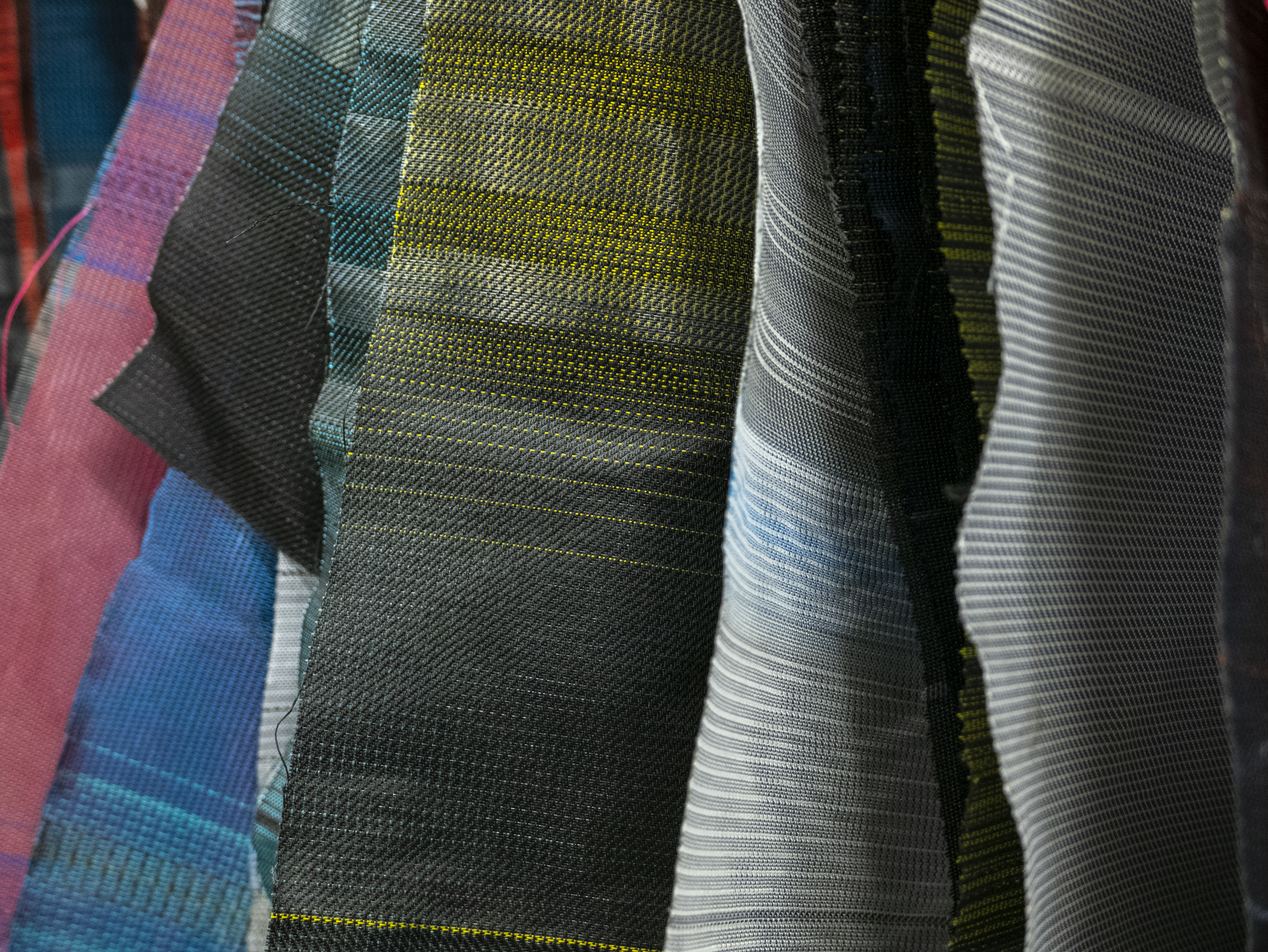

One of those factories is Chamatex. Chamatex developes textiles, fabrics and materials that are been used in the motorsport, but together with Mavix they’ve developed a new type of fabric named Matryx®.

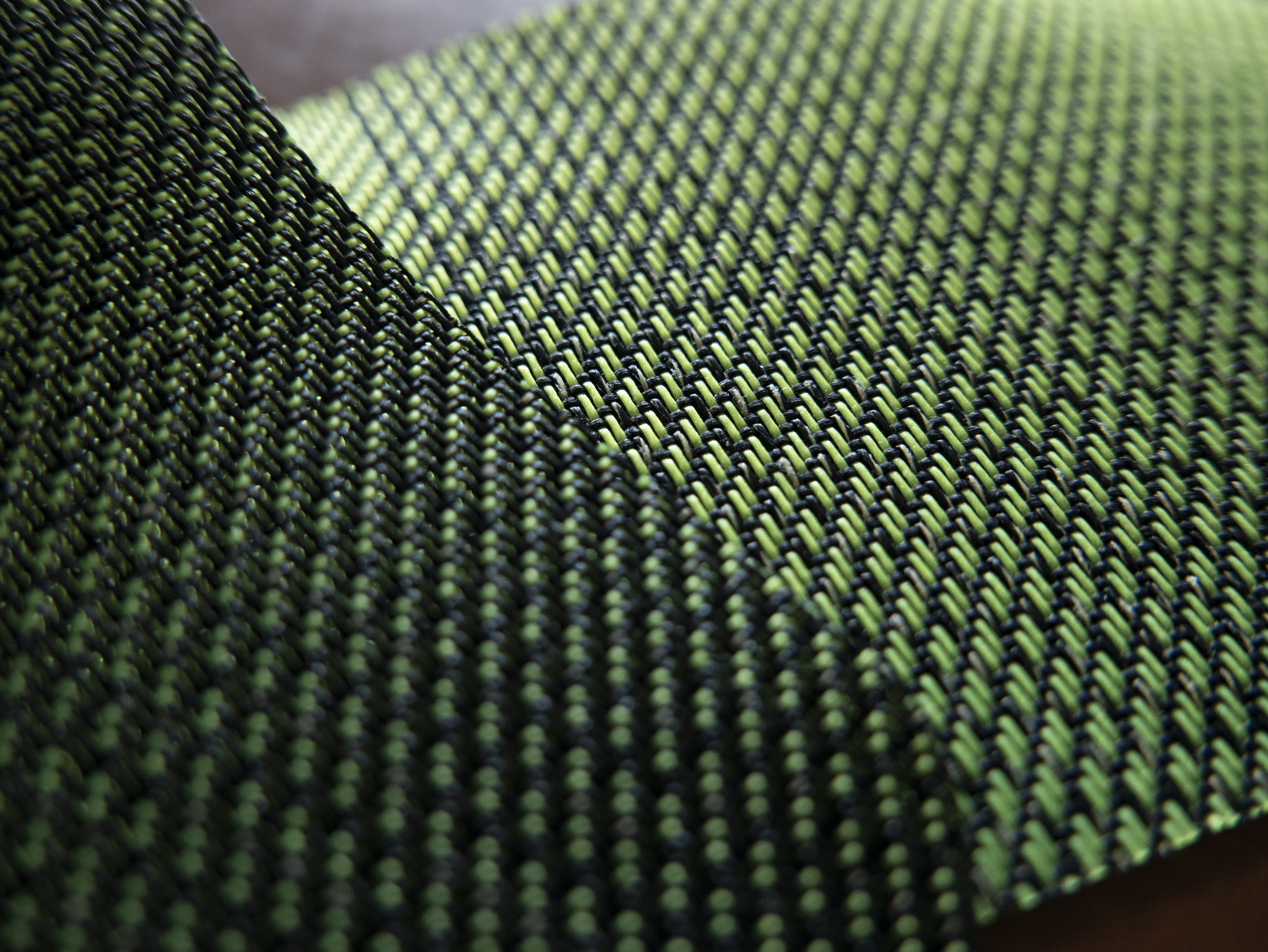

Matryx®, a patented technology using Kevlar®, Carbon and high tensity Polyamid. It provides outstanding abrasion resistance, foot-mapping support in the key areas, superior breathability and is light weight. The perfect fabric for the liner of the Comete Ultimate 2 or the All road shoes.

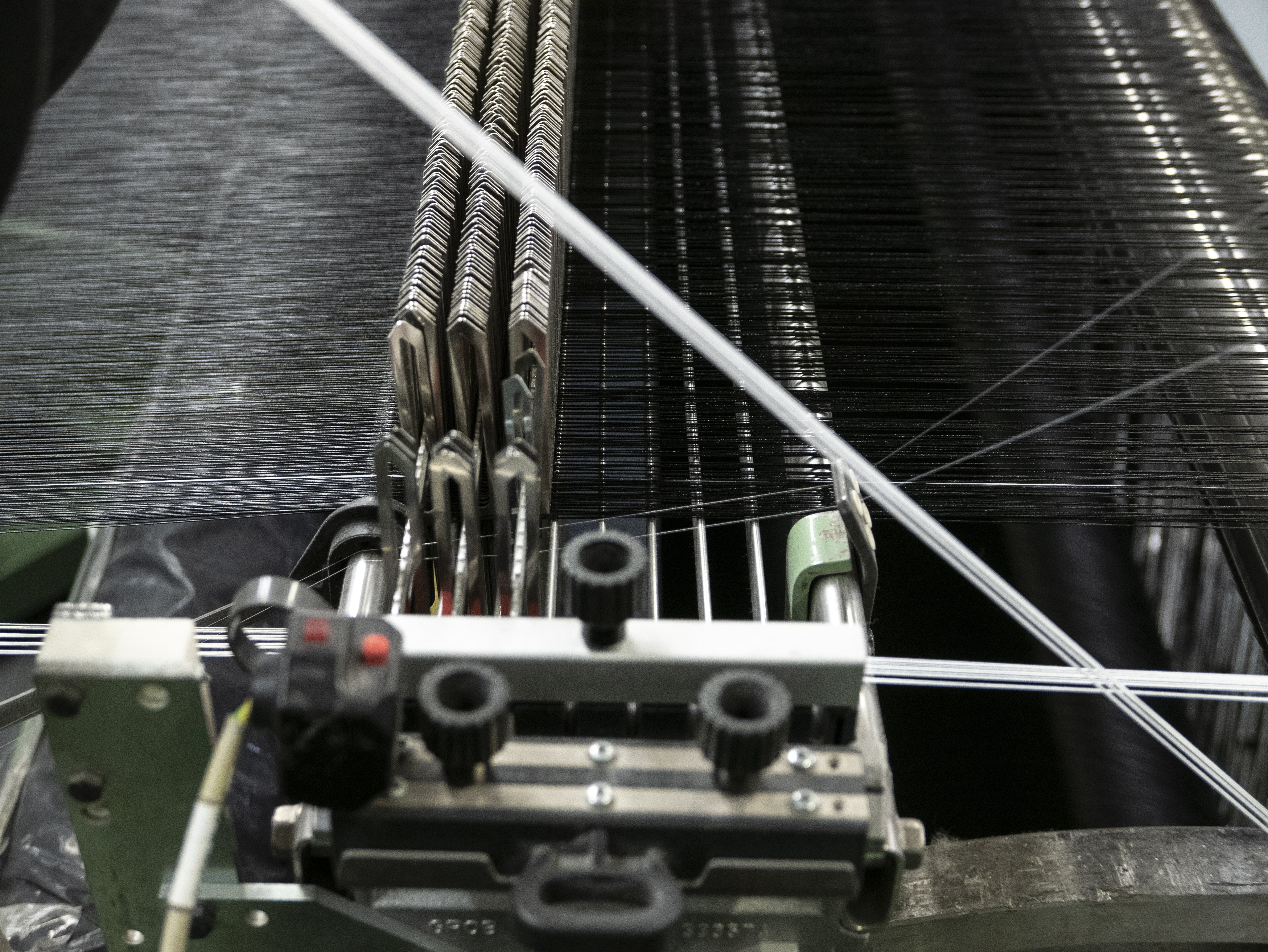

The other factory is Payen, here they gave us a tour inside the factory, a beautiful historical building, used to be a silk factory back in the day. This is were we got see the process of making a single yarn to the process of weaving, a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. This 4 way stretch woven fabric that they make, has been used in one of Mavic’s latest merino bibshorts.

Let’s start with visiting the Payen factory first, after we got picked up at the airport. Somehow we ended up playing golf and eat lunch inbetween pick up and factory arrival. Typical French I guess? Something worth mentioning but not documenting in the from of taking pictures apparently, but pretty sure we’re in France now.

Arrived at the Payen factory, you can still see some parts of the historical silk factory.

Let’s get inside, the moment we’ve all been waiting for. They gave use special noise cancelling headphones, because the machinery were pretty loud in there.

There’s a whole process in giving these yarns the right colour. Yellow mavic for instance.

You might think all those chemicals can’t be good to the environment, but this factory is actually located next to a river and it uses the water from the river in the process of dyeing the fabric. After the dyeing process the factory cleans the water and gives it back to the river, the factory is actually giving back cleaner water than the excisting water in the river.

Proper transfer to the Hotel. One of Mavic’s neutral service cars, one of those cars they use in the Tour the France.

Day two, visiting the Chamatex factory, this is where they make the textiles for the Comete Ultimate 2 and their gravel shoe the All Road.

Another factory and more yarns. But they saved the good stuff for later...

Shoes! And we all love shoes, especially these All Road samples. Wish I could take these home!

From a single yarn to a piece of fabric to the final product, the Comete Ultimate 2

Day 3, what is a press event without riding? So on day 3 we had to get up early, around 6:00, to be on time for our transfer to the start of the ride. This was no surprise for us as we already checked in our bikes at the airport. But what we didn’t know was that Mavic actually did had a surpise for us...Newkitday!

Ready to ride!

On our way to the most touristic part of the Ardèche, Vallon-Pont-d’Arc

And what goes up most come down.

Arrived at Pont d’Arc